Current Research

Aerobic Granular Sludge Reactor Design and Piloting

Granular sludge applications provide a biological process in which slow-growing populations (nitrifiers, polyphosphate-accumulating organisms, and anaerobic ammonia oxidizers) can be preserved within a fast-settling particle without ballast addition. Granules can be defined as discrete particles that do not need bio-flocculation to settle. The dense nature of granules results in excellent settling characteristics, thus smaller reactor volumes, or the potential to intensify existing treatment processes. The formation of aerobic granular sludge in low-strength municipal wastewater is being tested at the University of Kansas and the City of Lawrence Wastewater Treatment Plant.

Dr. Sturm is currently leading the WERF U1R14 project “Balancing Flocs and Granules for Activated Sludge Process Intensification in Plug Flow Configurations.” The project includes 7 full-scale wastewater treatment plants in three continents, each with a partnering engineering consulting firm.

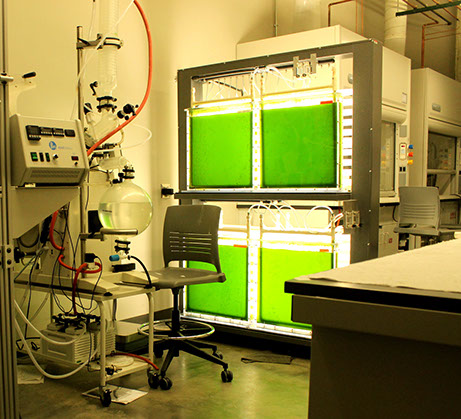

Algal Treatment Systems: Recovering Nutrients and Producing High-Value Products

Over the past 7 years, Dr. Sturm has collaborated with Dr. Susan Williams in Chemical Engineering to grow algae to recover biofuel and nutrients from municipal wastewater. Algae remove nitrogen and phosphorus from the wastewater as they assimilate the nutrients into new biomass growth. Using thermochemical conversion of the algae, the group has demonstrated the formation of a highly crystalline and well-ordered hydroxyapatite (stoichiometric HAp: Ca10(PO4)6(OH)2) product that recovers 95% of the P in algae. Potential applications for this recovered material include solid fertilizers, heterogeneous catalysts, and biomaterials for biomedical engineering. Ongoing research seeks to maximize phosphorus recovery from wastewater while generating high-value compounds.

Determining the Fate and Major Removal Mechanisms of Microplastics in Water and Resource Recovery Facilities

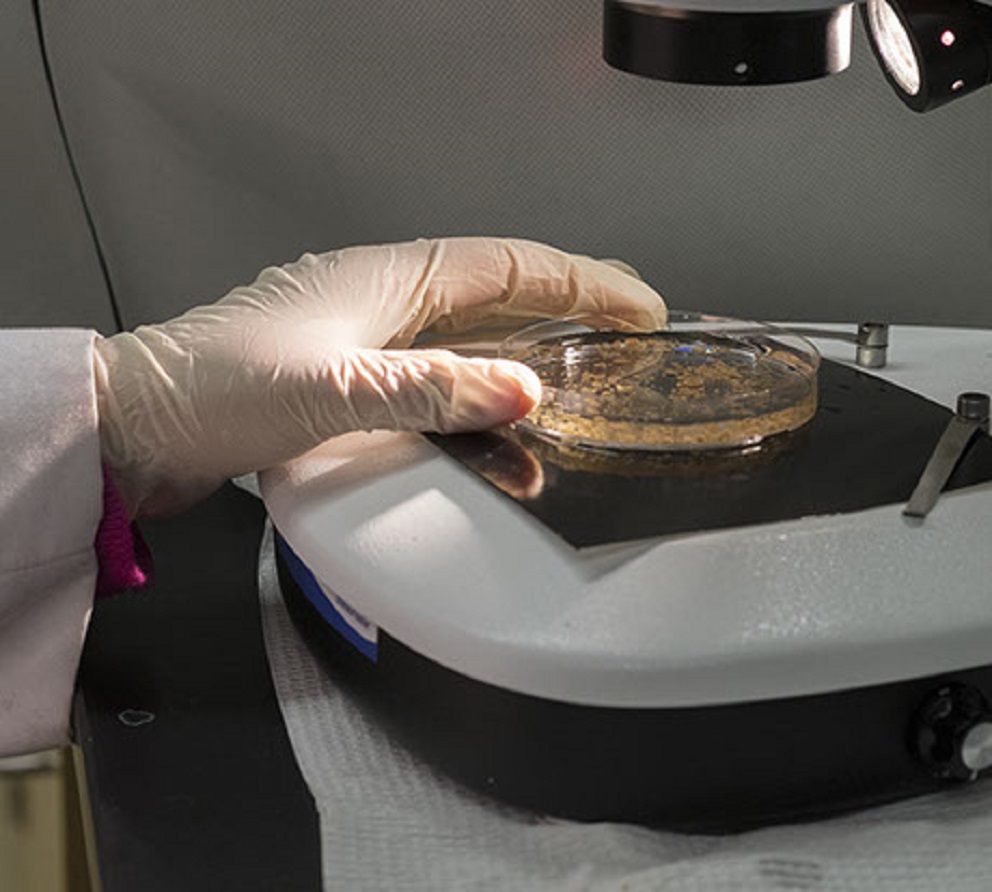

Plastic debris has become a major and growing global pollution problem as it ends up in aquatic environments where the large and coarse plastic is fragmented and divided into smaller fragments (microplastics) under environmental conditions. Microplastics are defined as plastic pieces smaller than 5 mm in size and have major environmental consequences. However, knowledge about microplastics is still very fragmentary. Special attention has been given to identifying the sources of microplastics. Wastewater treatment plants (WWTPs) have been described as a point of source for microplastics, but there is little information regarding the fate of microplastics inside the WWTPs itself. Dr. Sturm together with Dr. Edward Peltier was awarded a NSF grant to study the impact of microplastics.

In this project, we want to determine whether WWTPs act as a multiplier or decrease the microplastic load from the effluent. We hypothesize that activated sludge in WWTPs harbors microorganisms capable of plastic degradation and actively participates in degrading some portion of the microplastic contamination. We want to determine the fraction of microplastics degraded by the microbial population and the mechanism of the degradation. We’ll also test the effectiveness of absorption by activated sludge and physical screening in WWTPs on microplastic removal. Based on the obtained results, we’ll be able to formulate an effective mitigation-measure strategy for microplastics.

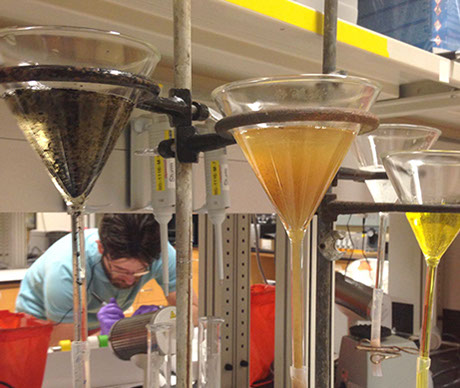

Improving Water Management, Treatment and Recovery in Oil and Gas Production

Unconventional oil and gas has become an increasingly significant industry in the United States, including in Kansas and West Virginia, motivating efforts to minimize the associated environmental impacts. Dr. Edward Peltier was awarded a NSF EPSCoR grant to study the treatment of produced water for beneficial reuse and safe disposal and understand the impacts of oil and gas exploration on aquatic ecosystems.

Dr. Sturm has collaborated with Dr. Peltier to investigate the following:

- Ability of bacteria to form aerobic granular sludge (AGS) in hypersaline oilfield produced water.

- Developing a treatment process for the removal of organic BTEX hydrocarbons from oil and gas produced water.

- Developing a treatment process for the removal of sulfur compounds in produced water.

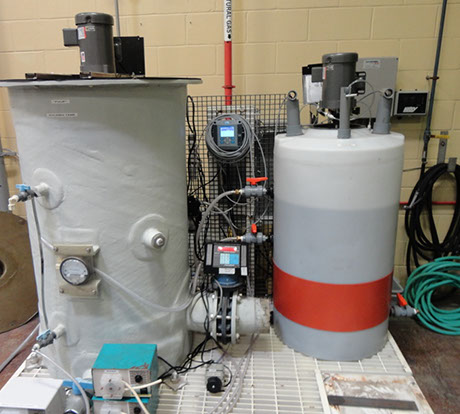

Pilot-Scale Anammox Reactor for Side-Stream Wastewater Treatment

In anaerobic ammonia oxidation (anammox) process, distance clad of Planctomycetes bacteria oxidize ammonia using nitrite as an electron acceptor under anaerobic condition. Combined nitritation-anammox has been confirmed as an attractive option for nitrogen removal in high-strength wastewater due to low cost and robustness. In this project, we have started-up a 265 L pilot-scale anammox plant for the City of Lawrence, Kansas. This industrial funded demonstration plant give us the opportunity to bring the state of art anammox process to the field. We have been engaged from successfully operating the process for treating side-stream wastewater to investigating the microbial community structure dynamics over a period of time. We’ll combine next-generation sequencing with other molecular techniques to understand the mechanisms of anammox metabolism in the pilot-scale plant.